10 Essential Tips for Well and Pump Maintenance Efficiency Guide?

In the well and pump industry, maintenance efficiency is crucial for optimal performance. According to a report by the Water Systems Council, about 90% of residential water systems depend on wells. Inadequate maintenance can lead to decreased efficiency and increased costs. “Proper maintenance is not just an option; it is a necessity,” states Dr. Jane Thompson, a leading expert in sustainable water systems.

Regular maintenance can extend the lifespan of both well and pump systems. Neglecting these tasks can create unexpected failures. Pumps operate under significant stress, leading to wear over time. The average lifespan of a well is 25 years, but this can be diminished by poor upkeep.

Every year, the cost related to well and pump repairs can reach thousands for property owners. Efficient maintenance practices can significantly reduce such unnecessary expenditures. It is vital to adopt proactive strategies. However, many owners fail to recognize warning signs that indicate the need for attention. Implementing simple, regular checks ensures reliability and saves money in the long run.

Understanding the Importance of Well and Pump Maintenance

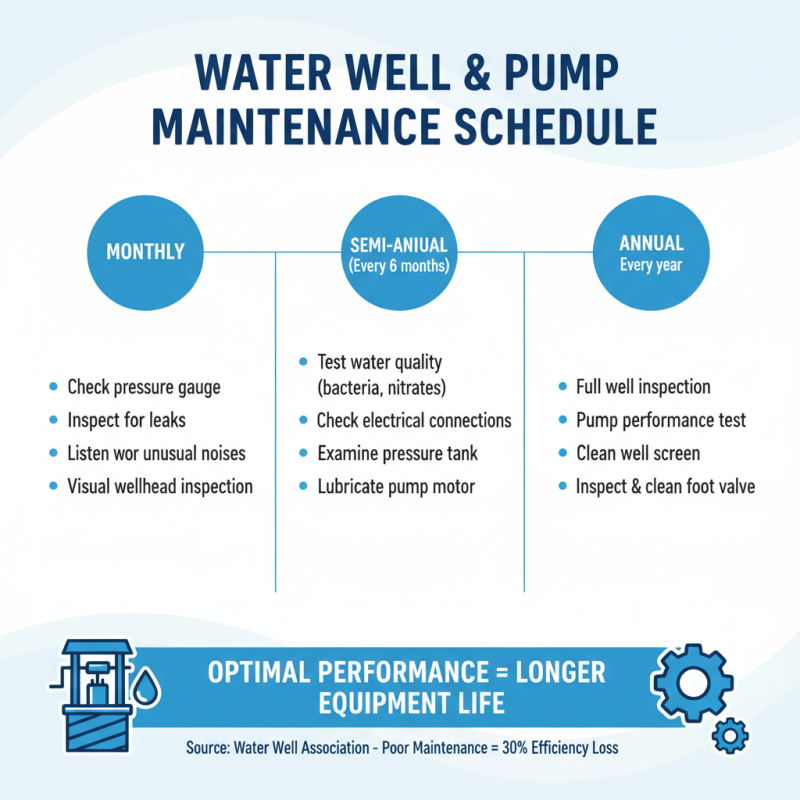

Well and pump maintenance is crucial for reliable water supply. According to industry reports, improper maintenance can lead to 30% efficiency loss in pump operations. Regular inspections prevent minor issues from becoming major problems. Neglecting these tasks can result in costly repairs and downtime.

Delay in fixing small leaks can escalate into significant water waste. Nearly 1 trillion gallons of water are wasted due to leaks in the U.S. alone. It's essential to check for wear and tear on components frequently. This simple practice can extend the life of a well system significantly.

Understanding the wear patterns in pumps is vital. Pump efficiency can drop dramatically over time if not monitored. Over 40% of pump failures occur due to poor maintenance. Adopt a preventive approach. This will not only save costs but also improve performance. Use checklists to stay organized and ensure all maintenance tasks are completed on schedule.

Key Components of Well and Pump Systems to Monitor Regularly

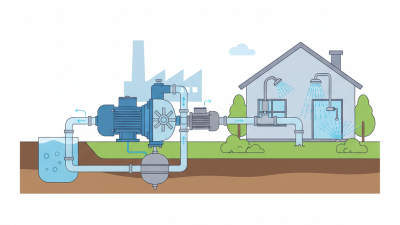

Maintaining well and pump systems is crucial for their longevity and efficiency. Key components require regular monitoring to prevent unexpected failures. One essential part is the pressure gauge. It shows whether the system operates within optimal levels. If the pressure is too high or low, it indicates potential problems.

Another important component is the check valve. It prevents backflow, ensuring that the water flows in the right direction. Regular inspection can help identify wear or blockages. This might be overlooked until a major issue arises. Additionally, look closely at the pump motor. Any unusual noise or vibration could signal that something is wrong. Early detection saves time and money.

Water quality should also be evaluated. High levels of sediment can damage pump systems. A filtration system may help. However, remember that no solution is perfect. Routine maintenance might be neglected due to busy schedules. Reflecting on priorities can improve these habits. Regular checks are essential to a healthy well and pump system.

Tips for Creating a Well and Pump Maintenance Schedule

Creating a well and pump maintenance schedule is essential for optimal performance. Regular upkeep can increase the lifespan of your equipment. According to the Water Well Association, a poorly maintained well can lead to a 30% decrease in efficiency. Regular checks can help prevent costly repairs and ensure reliable water supply.

Scheduling routine maintenance checks is crucial. Experts recommend creating a calendar that highlights key tasks. This includes changing filters every six months and inspecting pumps annually. One study showed that proactive maintenance can reduce downtime by 40%. Documenting each visit ensures nothing is overlooked and allows for better planning in the future.

Some users forget the importance of water quality testing. Ignoring this aspect can result in health risks and equipment damage. It's easy to overlook details, but a weekly check can make a difference. A thorough checklist should include not just physical inspections but also water testing. This preventive measure may seem tedious but can save money and avoid bigger issues down the line.

Common Issues and Solutions for Well and Pump Systems

Well and pump systems are vital for many households. However, they can experience several common issues. One major concern is low water pressure. This may result from a clogged filter or a deteriorating pump. Regular inspection and cleaning can help maintain optimal performance.

Additionally, unusual noises from the pump can indicate trouble. These noises can result from cavitation or air leaks. Ignoring these sounds could lead to expensive repairs. It’s crucial to act quickly to avoid further damage. Monitoring the system and addressing these noises can save time and money.

Lastly, frequent cycling of the pump is a common problem. This may occur due to a malfunctioning pressure switch or a leak in the system. A thorough examination of the components can help identify the source. Regular maintenance checks are essential for early detection of such issues. It may take time, but consistent effort can significantly enhance the longevity of well and pump systems.

10 Essential Tips for Well and Pump Maintenance Efficiency Guide

| Tip Number | Maintenance Tip | Common Issues | Solutions |

|---|---|---|---|

| 1 | Regular Inspections | Worn components | Replace as needed |

| 2 | Check Water Quality | Contaminants | Perform water testing |

| 3 | Maintain Electrical Components | Short circuits | Inspect wiring |

| 4 | Lubricate Pump Bearings | Noise during operation | Apply appropriate lubricant |

| 5 | Keep Equipment Clean | Debris accumulation | Regular cleaning |

| 6 | Inspect Well Cover | Cracks or leaks | Repair or replace |

| 7 | Monitor Pump Performance | Reduced output | Check for blockages |

| 8 | Test the Pressure Switch | Pump cycling frequently | Replace switch |

| 9 | Flush the System | Clogged pipes | Perform regular flushing |

| 10 | Consult a Professional | Severe issues | Hire an experienced technician |

Best Practices for Record Keeping and Routine Inspections

Effective record keeping is crucial in well and pump maintenance. Accurate logs help track performance and identify issues early. A study by the American Petroleum Institute showed that 30% of pump failures come from poor maintenance records. This indicates that a simple lack of organized documentation can lead to costly downtime.

Routine inspections also play a significant role in maintenance efficiency. Regular checks can prevent failures and extend equipment life. According to data from the National Association of Pump Manufacturers, pumps maintained on a scheduled basis perform 20% better than those that aren't. However, inconsistent inspection practices can lead to oversight of critical problems, such as leaks or wear. Operators often forget to check smaller components, which can result in larger issues down the line.

Utilizing digital platforms for record keeping can enhance maintenance efficiency. These tools allow for easy data entry and analysis. However, many operators still rely on outdated methods, leading to gaps in information. It's essential to not only collect data but to review and act on it regularly. Ignoring trends can cause unforeseen failures and increased operational costs. Regular training on best practices can mitigate these risks and ensure better adherence to maintenance schedules.

10 Essential Tips for Well and Pump Maintenance Efficiency Guide

Related Posts

-

2025 Top Well Pumps: A Comprehensive Guide to Performance and Efficiency

-

Top Tips for Choosing the Best Well and Pump Systems in 2025

-

What is a Water Pump and How Does it Work Explained Simply

-

How to Choose the Right Fluid Transfer Pump for Your Needs?

-

How to Choose the Best Well Pump for Your Home Water Needs

-

Top 10 Battery Pumps for Efficient Water Transfer and Easy Usage