10 Expert Tips to Choose the Right Fluid Pump for Your Industrial Application

Choosing the right fluid pump for your industrial application is a critical decision that can significantly impact operational efficiency and cost-effectiveness. According to a report by the Global Fluid Pump Market, the industry is projected to reach USD 57 billion by 2025, driven by increasing demand across various sectors such as oil and gas, water and wastewater management, and chemical processing. This growth underscores the necessity for businesses to make informed choices when selecting the appropriate fluid pump to optimize performance and sustainability.

Furthermore, in the context of evolving manufacturing processes and advanced technologies, understanding the myriad types of fluid pumps available is paramount. Factors such as fluid properties, application requirements, and energy efficiency ratings should play a vital role in the decision-making process. Industry studies reveal that improper pump selection can lead to operational inefficiencies, resulting in excess energy costs and maintenance issues, potentially costing companies millions annually. Thus, equipping oneself with expert insights and data-driven strategies is essential for effectively navigating the complexities of fluid pump selection in any industrial application.

Understanding Fluid Dynamics: Key Principles for Pump Selection in Industrial Settings

When selecting a fluid pump for industrial applications, understanding the fundamental principles of fluid dynamics is crucial. The behavior of fluids under various forces can significantly impact the efficiency and effectiveness of your pump system. Key considerations include flow rate, pressure, and viscosity. These parameters dictate the type of pump that will best suit your needs while ensuring optimal performance.

One expert tip is to carefully assess the viscosity of the fluid you’ll be pumping. High-viscosity fluids require specialized pump designs to maintain flow without excessive energy consumption. Another important factor is the net positive suction head (NPSH) that your pump requires. Ensuring system compatibility can prevent cavitation, which can severely damage the pump over time.

Additionally, consider the fluid's temperature and chemical properties. Pumps made from materials that can withstand the specific conditions of the fluid will offer greater longevity and reliability. Selecting the right fluid pump involves a comprehensive understanding of these dynamics, leading to more informed decision-making and improved operational efficiency.

10 Expert Tips for Choosing the Right Fluid Pump

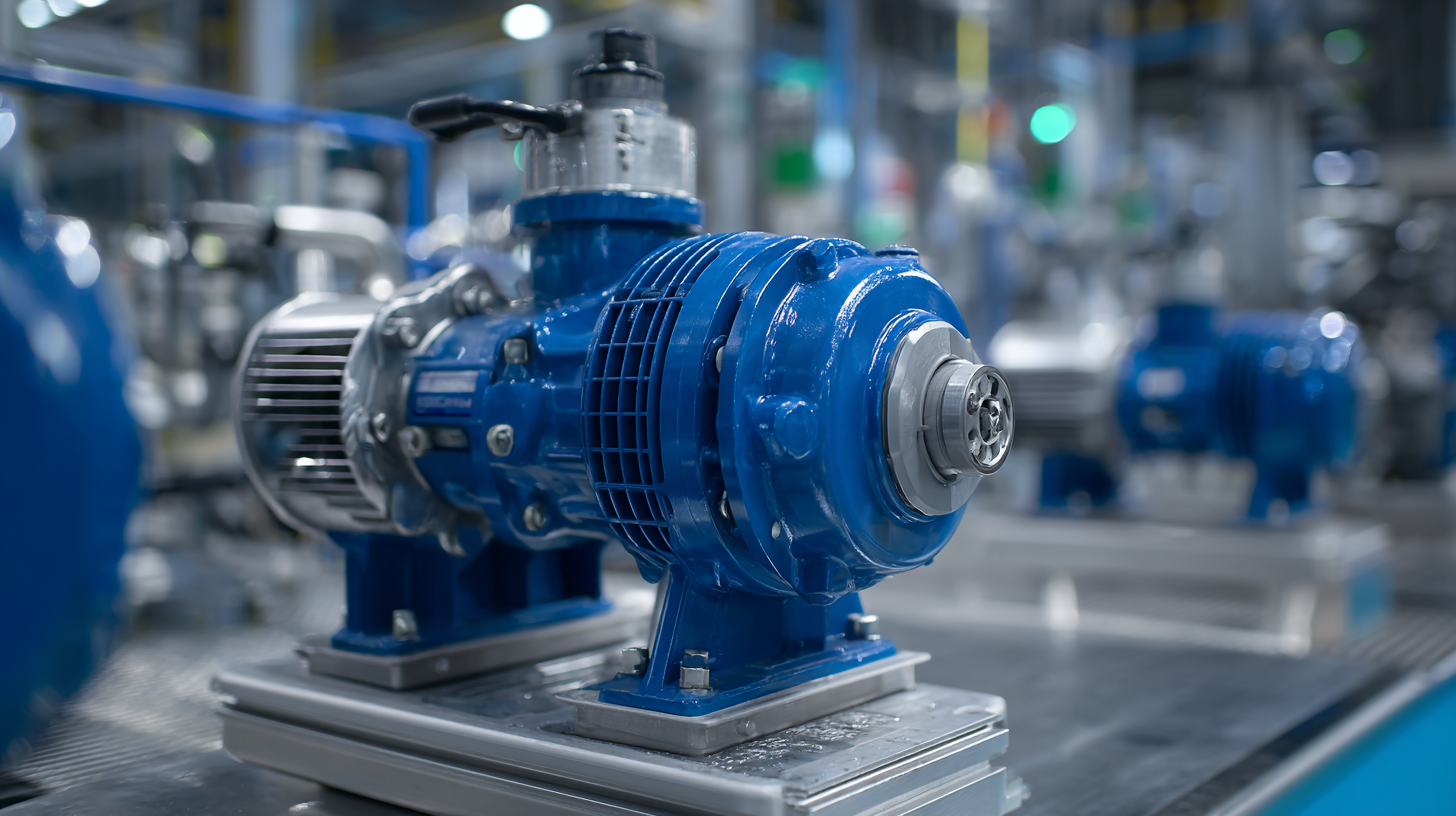

Evaluating Pump Types: Centrifugal vs. Positive Displacement for Specific Applications

When selecting a fluid pump for industrial applications, understanding the differences between centrifugal and positive displacement pumps is crucial. Centrifugal pumps, which operate using rotational energy to move fluids, are ideal for high flow rates and low-viscosity liquids. According to a report by the Hydraulic Institute, approximately 80% of all pumps installed in various industries are centrifugal due to their efficiency and low maintenance costs. These pumps are particularly suitable for applications like water treatment and chemical processing, where fluid dynamics play a vital role.

On the other hand, positive displacement pumps are designed to move a fixed amount of fluid with each cycle, making them perfect for high-viscosity fluids or applications requiring precise flow control. A study from the American Society of Mechanical Engineers highlights that positive displacement pumps are essential in industries such as oil and gas, where the ability to handle thick materials efficiently can significantly impact operational success. Furthermore, they maintain consistent flow rates regardless of pressure changes, which is a critical advantage in many demanding environments. Understanding the specific requirements of your application can guide you in selecting the pump type that delivers the best performance and reliability.

Assessing Performance Metrics: Flow Rate, Pressure, and Efficiency in Pump Selection

When selecting a fluid pump for industrial applications, it's critical to assess key performance metrics such as flow rate, pressure, and efficiency. The flow rate indicates the volume of fluid that the pump can move within a specific time frame, often measured in gallons per minute (GPM) or liters per minute (LPM). It's essential to match the pump's flow rate with the requirements of the application to ensure optimal performance and avoid potential system overloads or insufficient fluid delivery.

Pressure is another determining factor in pump selection. It indicates the force that the pump can exert to move fluid through the system. Understanding the system's pressure requirements is vital to prevent cavitation, which can damage the pump and reduce its lifespan. Additionally, evaluating the efficiency of the pump becomes critical for minimizing energy costs and maximizing productivity. A more efficient pump will not only reduce operational costs but also contribute to a more sustainable industrial process. Together, these performance metrics provide a comprehensive basis for selecting the most suitable fluid pump for your specific requirements.

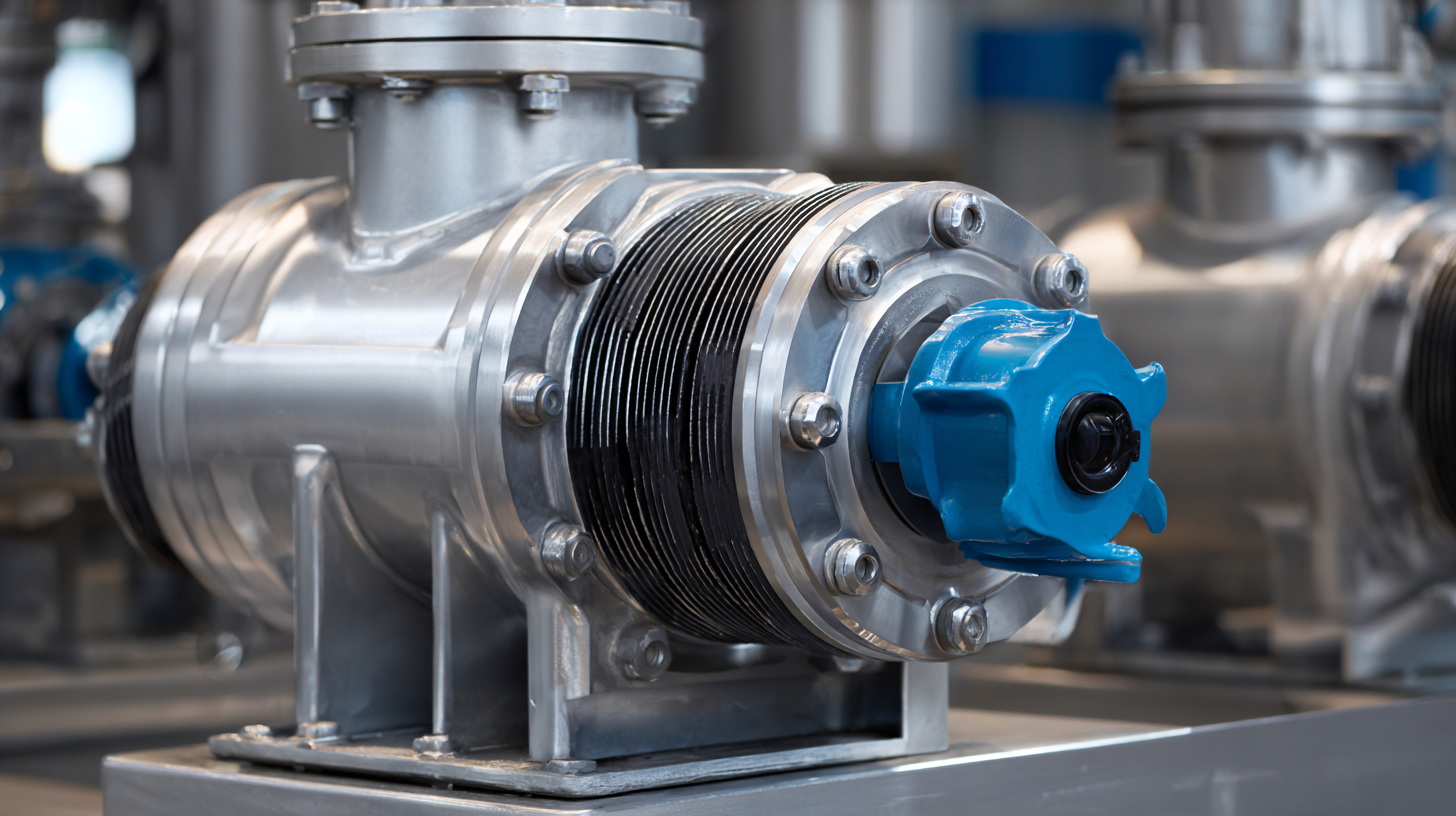

Material Compatibility: Ensuring Pump Longevity and Safety in Harsh Environments

When selecting a fluid pump for industrial applications, material compatibility is paramount, especially in harsh environments where aggressive chemicals like ethylene oxide are present. The longevity and safety of a pump heavily depend on its ability to withstand the chemical properties of the fluids it will handle. For instance, using a pump constructed from materials that are not compatible with ethylene oxide can lead to premature wear, failures, and even catastrophic leaks, posing safety hazards.

In addition to chemical compatibility, energy efficiency and containment play critical roles in selecting the right pump technology. Advanced pump designs incorporate features that enhance reliability and extend service life, which is especially crucial in industries dealing with hazardous materials. Employing solutions like AODD pump technology can provide better performance in challenging chemical environments while ensuring that the equipment remains operational for extended periods. Selecting the appropriate materials and technologies not only mitigates risks but also maximizes operational efficiency in the long run.

10 Expert Tips to Choose the Right Fluid Pump for Your Industrial Application - Material Compatibility: Ensuring Pump Longevity and Safety in Harsh Environments

| Application | Fluid Type | Pump Type | Material Compatibility | Operating Conditions | Recommended Seal Material |

|---|---|---|---|---|---|

| Chemical Processing | Acids | Diaphragm Pump | Polypropylene | High Temperature, High Pressure | PTFE |

| Food & Beverage | Oil | Gear Pump | Stainless Steel | Ambient Temperature | EPDM |

| Pharmaceutical | Solvents | Peristaltic Pump | Silicone | Controlled Environment | Silicone |

| Wastewater Treatment | Sludge | Submersible Pump | Cast Iron | Variable Temperature | Nitrile |

| Oil & Gas | Crude Oil | Centrifugal Pump | Alloy Steel | Extreme Conditions | Viton |

Cost Analysis: Balancing Initial Investment with Long-Term Operational Costs in Pump Choices

When selecting a fluid pump for industrial applications, it’s essential to consider not just the initial purchase cost but also the long-term operational expenses. Industry reports indicate that almost 70% of the total lifetime costs of a pump can come from maintenance and energy consumption, highlighting the importance of thorough cost analysis during the selection process. For instance, a study by the Hydraulic Institute revealed that optimizing pump efficiency can lead to energy savings of 20-50%, significantly impacting the overall budget over the pump's lifespan.

Furthermore, various types of pumps offer different maintenance requirements and operational efficiencies. Positive displacement pumps, while often more costly upfront, can deliver lower energy costs and reduced downtime due to their reliability. Research in the Journal of Fluid Engineering highlighted that investing in higher-quality pumps can yield up to a 30% reduction in operational costs over a decade, justifying the higher initial investment. Therefore, prospective buyers must weigh the upfront costs against these critical long-term financial implications to ensure sustainable and economical operations.

Related Posts

-

Revolutionizing Pump Systems with IoT Integration for Enhanced Efficiency and Performance

-

Exploring the Benefits of Food Pumps for Efficient Culinary Experiences

-

Understanding the Benefits of a Food Pump for Home Cooking Efficiency

-

Understanding the Importance of Lab Pumps in Modern Scientific Research

-

Understanding the Importance of Transfer Pumps in Everyday Life: A Complete Guide

-

Understanding the Benefits of Motor Driven Diaphragm Pumps in Industrial Applications